In the last decade, data science has seen an immense influx in various industrial applications across the board. Today, we can see data science applied in every industrial process in every sector. Among these, manufacturing has gained more prominence to achieve a simple goal of customer delight, and efficiencies through Just-in-Time (JIT).

In the last many decades, manufacturing has gone through four major industrial revolutions. Currently, we are going through the fourth Industrial Revolution, where data from customers, machines, environment, and products are being harvested to get closer to that simple goal of Just-in-Time; “Making the right products in right quantities at a great customer value, at the right time.” One might ask why JIT is so important in manufacturing? The simple answer is to reduce the manufacturing cost and make products more affordable, and of highest quality for everyone.

Organizations like Asian Paints that has been at the forefront of applying technology in manufacturing for the last 40 years, have been using data science to deliver, their paint products, that are in demand, with an unimaginable precision – products delivered to their 70,000 outlets across India, gets sold within 3 hours. Their delivery fleets visit these outlets every 3-4 hours, every day, to deliver what the customers need with amazing efficiency and to the utter delight of not just customers, but also of every outlet owner! No wonder that Harvard University’s case on Asian Paints, says “India’s biggest data company, that manufactures paints”

By Integrating Data Science and AI in the strategy making and execution, Manufacturing companies in Africa, for example, here I am going to talk about two diverse manufacturing companies from Tanzania who participated in the March 2024 DSAIRe in Dar Es Salaam – Vita Foam (T) Limited – manufacturing sleeping solutions (home product) and Superdoll – manufacturing large truck trailers (Large industrial product) – can easily grow their bottom-lines by 10-20% above the normal expected growth that it will, otherwise gain, in a couple of years. These solutions I am going to discuss will be applicable to any manufacturing entity any where in the world, let alone any country of Africa.

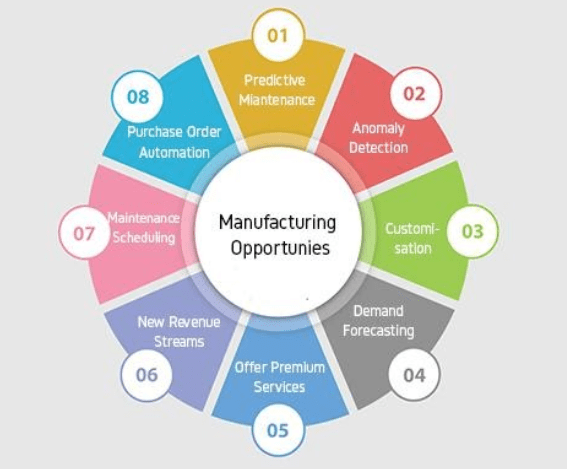

Manufacturing companies can embrace data science and AI by applying them in the following areas of its complete business value chain –

1. Product Innovation:

– Market Research: Employ data science techniques to analyze market trends, customer preferences, and competitor products, aiding in the development of innovative solutions.

– Customer Feedback Analysis: Utilize sentiment analysis and customer feedback mining to gain insights into product performance and areas for improvement.

2. Market Intelligence:

– Data science can analyze market trends, competitor strategies, and customer feedback, providing valuable insights for strategic decision-making and market positioning.

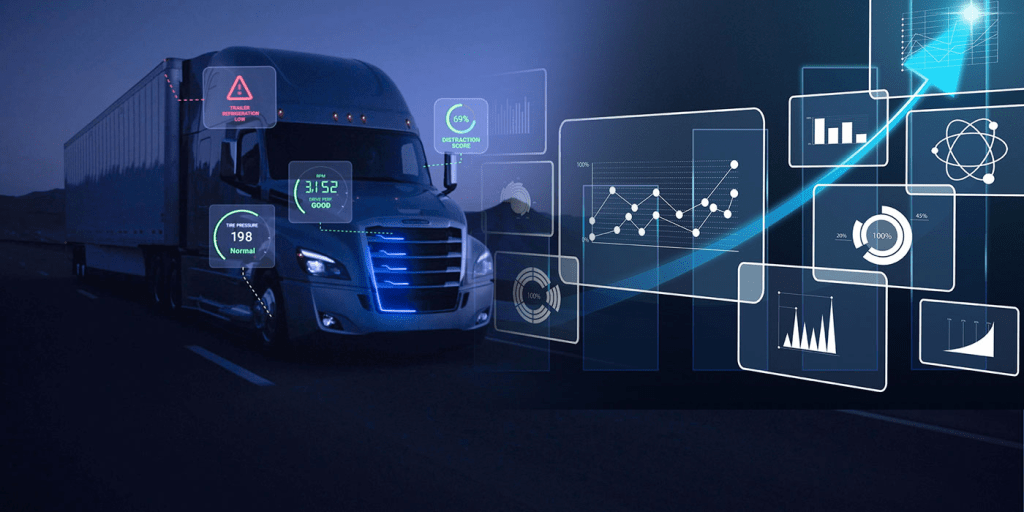

The COO of Superdoll, a very large big-machinery manufacturing company, talking about how the learning from DSAIRe is going to be of immense value to the organization

3. Supply Chain Optimization:

– AI can be used for demand forecasting, helping manufacturing Industries optimize inventory levels and production schedules.

– Data analytics can improve supply chain visibility, allowing for better decision-making in procurement, logistics, and real-time tracking to optimize distribution.

4. Quality Control and Assurance:

- Data science techniques such as machine learning can be applied to analyze production data and identify patterns related to product defects.

- AI-powered vision / imaging systems can also be used for real-time quality inspection, ensuring that only high-quality products are delivered to customers.

5. Predictive Maintenance:

- Implementing predictive maintenance using AI algorithms can help Manufacturing Industries predict when equipment is likely to fail or require maintenance. This can minimize downtime, reduce maintenance costs, and optimize production schedules.

- IoT sensors with data analytics can also be utilized to monitor machinery health, predict equipment failures, and schedule proactive maintenance.

6. Energy Efficiency:

- AI algorithms can optimize energy usage within manufacturing industries’ facilities by analyzing energy consumption patterns and identifying opportunities for efficiency improvements. This can lead to cost savings and reduce the environmental footprint of production operations.

7. Customized Solutions:

- AI can be used to analyze customer data and preferences, enabling Vita Foam (T) Limited Industries to offer personalized and customized sleeping solutions tailored and for Superdoll, embedded IOT solutions to predict vehicle breakdown possibilites, as much as monitoring the fuel efficiency parameters of the trailers etc to add immense value to the customers.

8. Operational Efficiency:

- Process Optimization: Apply data analytics to identify bottlenecks and inefficiencies in manufacturing processes, optimizing workflow for increased productivity.

- Employee Productivity: Use of AI to analyze employee performance data at any labour intensive manufacturing facilities and offices, and identify areas for skill development or process improvement, workforce productivity, automate routine tasks and improve overall efficiency.

9. Cost Optimization:

- Cost Analysis: A manufacturing entity can use data analytics to identify cost-saving opportunities in procurement, production, and distribution processes.

- Budget Forecasting: Apply predictive analytics to forecast budgetary requirements and optimize financial planning.

The CEO and COO of one of the largest sleeping solutions company, talking about how learnings from the DSAIRe is going to impact the organization, through process improvement etc.

10. Customer Relationship Management (CRM):

- Personalized Marketing: Utilize AI to analyze customer data and personalize marketing strategies, enhancing customer engagement and loyalty.

- Predictive Analytics: Anticipate customer needs and preferences, enabling to tailor their products and services accordingly.

11. Logistics and Distribution:

- Use AI for route optimization, vehicle scheduling, and warehouse management to streamline logistics operations.

- Implement predictive maintenance for fleet vehicles to minimize downtime.

12. Regulatory Compliance:

- Data science can assist in monitoring and ensuring compliance with industry regulations, quality standards, and environmental sustainability requirements at Vita Foam (T) Limited and also Superdoll.

12. Cybersecurity:

- Last but not least AI-driven Security: Implement AI-based cybersecurity solutions to detect and respond to potential cyber threats, ensuring the security of sensitive business data.

The team of data science and strategy consultants from IIT Madras Zanzibar, Zindi and CL Educate can help Vita Foam (T) Limited Industries as well as Superdoll to assess their specific business needs and challenges, look at the low hanging fruits that can be of value across the enterprises and also prioritize the pain points to address, and determine the most effective applications of data science and AI, and facilitate in developing and implementing tailored solutions.